From Contaminants to Clarity: A Comprehensive Guide to Solving Low RNA Purity in Extraction Protocols

Achieving high-purity RNA is a critical yet often elusive goal in molecular biology, with significant implications for the reliability of downstream applications in research, diagnostics, and therapeutic development.

From Contaminants to Clarity: A Comprehensive Guide to Solving Low RNA Purity in Extraction Protocols

Abstract

Achieving high-purity RNA is a critical yet often elusive goal in molecular biology, with significant implications for the reliability of downstream applications in research, diagnostics, and therapeutic development. This article provides a systematic framework for researchers and scientists to diagnose, troubleshoot, and overcome the pervasive challenge of low RNA purity. We explore the foundational causes of contamination—from organic solvent carryover to genomic DNA and protein—and detail targeted methodological optimizations for diverse sample types, including challenging tissues and viral vectors. A dedicated troubleshooting section offers step-by-step solutions for common extraction artifacts, while a final segment establishes rigorous validation and comparative metrics to ensure RNA quality meets the stringent demands of modern techniques like next-generation sequencing and clinical assay development. By synthesizing current best practices and innovative protocol modifications, this guide aims to standardize approaches and enhance reproducibility across biomedical and clinical research.

Understanding the RNA Purity Crisis: Why Contaminants Sabotage Your Research

This technical support center is framed within a thesis research context focused on solving low RNA purity in extraction protocols. For researchers and drug development professionals, accurate assessment of RNA purity via spectrophotometric ratios (A260/280 and A260/230) is critical for downstream applications like qPCR, RNA-seq, and microarray analysis. This guide provides troubleshooting and FAQs for common issues.

Troubleshooting Guides & FAQs

Q1: My RNA sample has an A260/280 ratio below 1.8. What does this indicate and how can I troubleshoot it? A: A low A260/280 ratio typically indicates protein contamination (e.g., from incomplete phenol removal during extraction) or residual guanidine salts. A ratio above 2.0 suggests possible RNA degradation or contamination with nucleotides.

- Troubleshooting Steps:

- Repeat Purification: Perform an additional clean-up step using a silica-membrane column or ethanol precipitation.

- Verify Protocol: Ensure proper phase separation during phenol-chloroform extraction. Avoid taking the interphase.

- Assess Integrity: Check RNA integrity on an agarose gel or Bioanalyzer; degraded RNA can give skewed ratios.

Q2: What causes a low A260/230 ratio, and how do I resolve it? A: A low A260/230 ratio (<2.0) is a primary focus of purity optimization research. It signifies contamination with chaotropic salts (guanidine thiocyanate), phenol, EDTA, or carbohydrates.

- Troubleshooting Steps:

- Increase Wash Buffers: Use the recommended volume of ethanol-based wash buffers (often 80%) and ensure complete dispensing.

- Extended Drying: After washing, let the column air-dry for 2-5 minutes before elution to evaporate residual ethanol.

- Elution Buffer: Elute with nuclease-free water instead of TE buffer, as EDTA severely depresses the A260/230 ratio. Pre-heat elution buffer to 65°C for higher yield.

- Protocol Adjustment: For TRIzol-based methods, ensure adequate washing of the pellet with 75% ethanol.

Q3: My spectrophotometer gives good purity ratios, but my qPCR fails. Why? A: Spectrophotometry cannot detect all contaminants. Residual RNase inhibitors (e.g., DEPC), alcohols, or column particulates can inhibit enzymatic reactions.

- Troubleshooting:

- Use Fluorometry: Quantify RNA with a dye-binding assay (e.g., RiboGreen) for greater accuracy in the presence of contaminants.

- Perform a Spike-in Control: Use a control RNA in your RT-qPCR to detect inhibition.

- Analyze Integrity: Always corroborate spectrophotometry with an integrity number (RIN) from a bioanalyzer.

Key Purity Metrics and Interpretations Table

| Metric (Ratio) | Ideal Value (Pure RNA) | Low Value Interpretation | High Value Interpretation | Common Contaminant |

|---|---|---|---|---|

| A260/280 | 1.8 - 2.0 (in 10mM Tris pH 7.5) | <1.8: Protein or Phenol contamination | >2.0: RNA degradation, high free nucleotides, or residual guanidine | Proteins, Phenol, Guanidine |

| A260/230 | 2.0 - 2.2 (can be method-dependent) | <2.0: Salt, carbohydrate, or organic solvent (phenol, ethanol) contamination | >2.2: Less common; may indicate degraded RNA or low sample concentration | Guanidine salts, Phenol, EDTA, Carbohydrates |

Experimental Protocol: Phenol-Ethanol RNA Clean-up for Low A260/230 Ratio

This protocol is cited as a key methodology in the thesis for remedying salt/organic contaminant issues.

- Precipitate RNA: To your aqueous RNA sample, add 0.1 volumes of 3M sodium acetate (pH 5.2) and 2.5 volumes of ice-cold 100% ethanol. Mix and incubate at -20°C for ≥30 minutes.

- Pellet RNA: Centrifuge at >12,000 x g for 30 minutes at 4°C.

- Wash Pellet: Carefully discard supernatant. Wash the pellet with 1 mL of freshly prepared 75% ethanol (in DEPC-treated water). Vortex briefly and centrifuge at 12,000 x g for 10 minutes at 4°C.

- Repeat Wash: Critical Step: Repeat the 75% ethanol wash once more to thoroughly remove salts.

- Dry Pellet: Air-dry the pellet for 5-10 minutes until no ethanol is visible. Do not over-dry.

- Resuspend: Dissolve the purified RNA pellet in an appropriate volume of pre-heated (65°C) nuclease-free water.

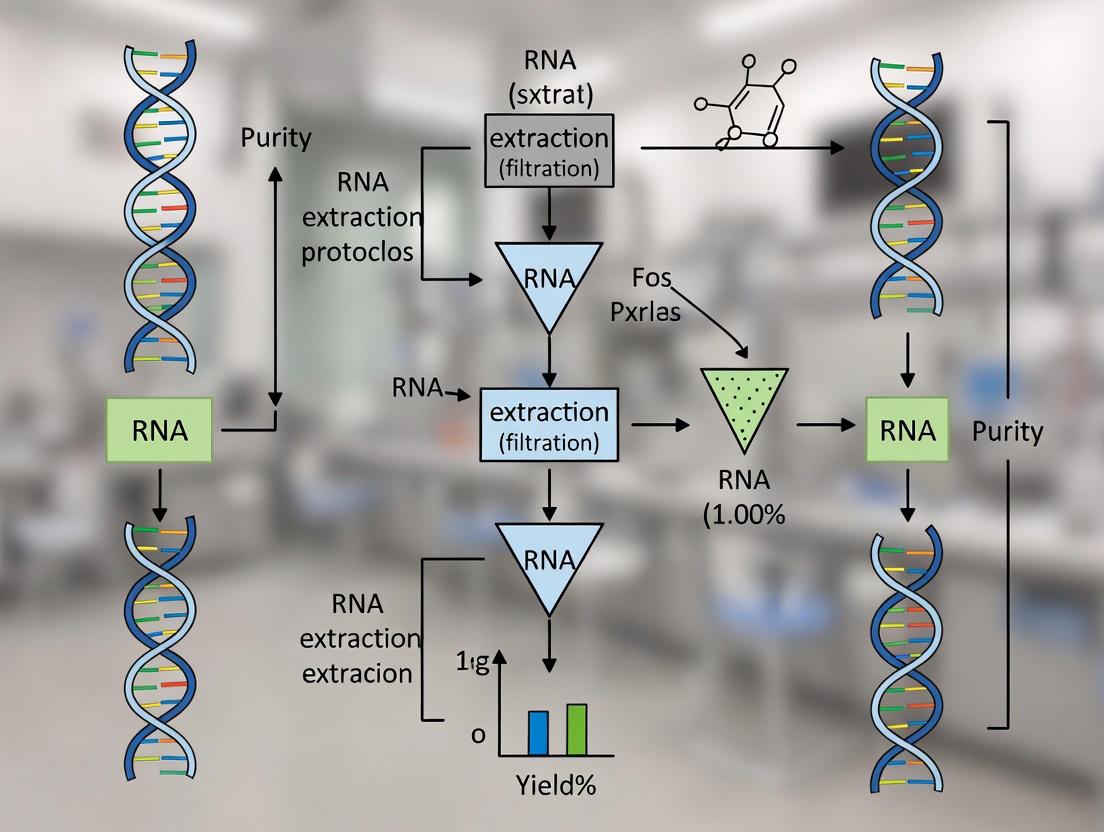

Visualization: RNA Purity Assessment & Remediation Workflow

Title: RNA Purity Troubleshooting Decision Tree

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in RNA Purity Context |

|---|---|

| Silica-membrane Spin Columns | Selective binding of RNA for separation from contaminants like salts and proteins. |

| Acid Phenol:Chloroform (pH 4.5-5.0) | Denatures proteins and partitions DNA to organic/interphase, leaving RNA in aqueous phase. |

| Guanidine Thiocyanate | Potent chaotropic agent that denatures RNases and proteins while aiding RNA binding to silica. |

| RNase-free Ethanol (75-80%) | Wash buffer component that removes salts without eluting bound RNA from silica membranes. |

| Sodium Acetate (3M, pH 5.2) | Provides cations for efficient ethanol precipitation of RNA, aiding in salt contaminant removal. |

| Nuclease-free Water (pH ~7.0) | Optimal, non-interfering elution buffer for spectrophotometry, avoiding EDTA from TE buffer. |

| RiboGreen / Qubit RNA Assay | Fluorometric quantification insensitive to common spectrophotometric contaminants (salts, organics). |

| RNA Integrity Number (RIN) Chip | Microfluidic electrophoretic analysis providing a numerical score of RNA degradation. |

Troubleshooting Guides & FAQs

FAQ 1: My RNA has low A260/A280 and A260/A230 ratios. What contaminants are likely present? Low A260/A280 (<1.8) often indicates protein or organic solvent (e.g., phenol, guanidinium salts) contamination. Low A260/A230 (<2.0) typically suggests carryover of salts, carbohydrates, or EDTA. gDNA contamination does not significantly alter these ratios but will manifest as high baseline in qPCR and smeared bands on agarose gels.

FAQ 2: How can I confirm the presence of gDNA in my RNA sample? Perform a no-reverse transcription (no-RT) control in your qPCR assay using an intron-spanning primer set. A significant Cq value (e.g., <5 cycles difference from the +RT sample) indicates substantial gDNA contamination. Alternatively, run the RNA on a 1% agarose gel; a high molecular weight smear or band above the 28S rRNA band suggests gDNA.

FAQ 3: My downstream cDNA synthesis is failing. Could salts be the culprit? Yes. High concentrations of chaotropic salts (e.g., guanidinium) or sodium ions from wash buffers can inhibit reverse transcriptase and polymerase enzymes. A common sign is poor yield or failure in cDNA synthesis and subsequent PCR, even with good RNA absorbance ratios.

Experimental Protocol: Assessing and Remedying gDNA Contamination

- Method: DNase I Treatment with Acid-Phenol:Chloroform Clean-up.

- Steps:

- To 20 µg of RNA in 50 µL of nuclease-free water, add 5 µL of 10X DNase I Reaction Buffer and 3 µL of RNase-free DNase I (2 U/µL).

- Incubate at 37°C for 30 minutes.

- Add 50 µL of nuclease-free water and 100 µL of acid-phenol:chloroform (pH 4.5). Vortex vigorously.

- Centrifuge at 12,000 × g for 5 minutes at 4°C.

- Transfer the upper aqueous phase to a new tube.

- Precipitate RNA with 0.1 volume of 3M sodium acetate (pH 5.2) and 2.5 volumes of 100% ethanol. Incubate at -20°C for 1 hour.

- Centrifuge at 12,000 × g for 30 minutes at 4°C. Wash pellet with 75% ethanol.

- Air-dry pellet and resuspend in nuclease-free water.

Experimental Protocol: Removing Organic Solvent and Protein Contamination

- Method: Selective Precipitation with Lithium Chloride.

- Steps:

- After the initial RNA isolation, add 0.1 volume of 3M lithium chloride (LiCl) to the aqueous RNA solution. Final LiCl concentration should be ~0.3M.

- Incubate at -20°C overnight. LiCl selectively precipitates RNA while leaving many proteins, carbohydrates, and residual organics in solution.

- Centrifuge at 12,000 × g for 30 minutes at 4°C.

- Carefully discard supernatant. Wash the pellet with 70% ethanol (made with nuclease-free water) to remove residual LiCl salts.

- Centrifuge again for 10 minutes. Air-dry pellet and resuspend in nuclease-free water.

Table 1: Spectral Ratios and Associated Contaminants

| Absorbance Ratio | Typical Pure RNA Value | Low Value Indicates | Common Source in Extraction |

|---|---|---|---|

| A260/A280 | ~2.0-2.2 | Protein, Phenol, Guanidine | Incomplete removal of lysis reagent, poor phase separation |

| A260/A230 | >2.0-2.5 | Salts, EDTA, Carbohydrates, Guanidine | Incomplete ethanol washes, carryover from wash buffers |

| A230/A260 | Not Applicable | Organic Compounds | Residual ethanol, phenol, chloroform |

Table 2: Impact of Common Contaminants on Downstream Applications

| Contaminant Type | Effect on Reverse Transcription | Effect on qPCR/ PCR | Effect on Microarrays/ Sequencing |

|---|---|---|---|

| gDNA | Not directly affected. | False positives, high background, reduced precision. | Altered expression profiles, inaccurate mapping. |

| Protein | Inhibits enzyme; reduces yield. | Inhibits polymerase; reduces efficiency. | Non-specific binding, high background noise. |

| Salts (Chaotropic) | Severe inhibition. | Severe inhibition, altered melting temps. | Interference with labeling, hybridization artifacts. |

| Organic Solvents | Denatures enzyme; complete failure. | Inhibits reaction; complete failure. | Degradation of sample, platform damage. |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Mitigating Contamination |

|---|---|

| RNase-free DNase I | Enzymatically digests residual genomic DNA in RNA samples. |

| Acid-Phenol:Chloroform (pH 4.5) | Used for clean-up after DNase treatment; removes proteins and enzymes while retaining RNA in aqueous phase. |

| Lithium Chloride (LiCl) | Selective precipitant for RNA; effective for removing co-precipitated proteins and organics. |

| SPRI (Solid Phase Reversible Immobilization) Beads | Bind RNA selectively in high ethanol; allow stringent salt/ethanol washes to remove contaminants. |

| Inhibition-Resistant Reverse Transcriptase | Engineered enzymes with higher tolerance to common contaminants like salts and alcohols. |

| gDNA Removal Columns | Silica membranes or filters that selectively bind gDNA during RNA kit protocols. |

| β-Mercaptoethanol / DTT | Reducing agents added to lysis buffers to disrupt protein disulfide bonds and inhibit RNases. |

Visualizations

Diagram 1: RNA Purity Assessment Workflow

Diagram 2: Contaminant Inhibition Pathways in cDNA Synthesis

Technical Support Center

Troubleshooting Guide

Issue 1: Inconsistent qPCR/RT-qPCR Results (High Ct, Poor Replicates)

- Potential Cause: Residual guanidinium salts or phenol from extraction inhibiting reverse transcriptase or DNA polymerase.

- Solution: Implement a post-extraction cleanup using a silica-membrane column or bead-based system with a high-salt ethanol wash. Verify purity via A260/A230 ratio; target >2.0. Dilute template 1:5 to reduce inhibitor concentration if ratio is low.

- Protocol: Post-Extraction Clean-up Protocol (Spin Column):

- Adjust RNA sample to 100 µL with RNase-free water.

- Add 350 µL of Buffer RLT (or similar high-salt chaotropic buffer) and 250 µL of 100% ethanol. Mix thoroughly by pipetting.

- Transfer mixture to a silica-membrane spin column. Centrifuge at >10,000 x g for 30 seconds. Discard flow-through.

- Add 500 µL of Buffer RPE (wash buffer). Centrifuge for 30 sec. Discard flow-through.

- Centrifuge column for 2 minutes to dry membrane.

- Elute RNA in 30-50 µL of RNase-free water by centrifugation.

Issue 2: Biased RNA-Seq Library Preparation (3' Bias, Low Complexity)

- Potential Cause: Degraded RNA (low RIN/RQN) or carryover of RNases.

- Solution: Use an automated electrophoresis system (e.g., TapeStation, Bioanalyzer) to assess RNA Integrity Number (RIN). Only proceed if RIN > 8 for standard mRNA-seq. For degraded samples, use a ribosomal depletion kit over poly-A selection.

- Protocol: RNA Integrity Assessment via Capillary Electrophoresis:

- Prepare RNA sample at ~50-500 pg/µL concentration.

- Denature RNA ladder and samples at 70°C for 2 minutes, then place immediately on ice.

- Load the RNA ladder into the appropriate well of an RNA assay chip.

- Load samples into subsequent wells. Vortex chip and run on the instrument.

- Analyze electropherogram peaks. Software calculates RIN (1-10) based on 18S and 28S rRNA peak ratios and presence of degradation products.

Issue 3: Reduced Transfection Efficiency for Therapeutics (e.g., mRNA Vaccines, ASOs)

- Potential Cause: Presence of endotoxins, proteins, or genomic DNA triggering immune responses or off-target effects.

- Solution: Use extraction kits certified for endotoxin-free processes. Include a DNase I digestion step (on-column is preferred). Quantify genomic DNA contamination using a no-reverse-transcriptase control in qPCR.

- Protocol: On-Column DNase I Digestion Protocol:

- After the first wash step during silica-column RNA extraction, prepare a DNase I digestion mix: 10 µL DNase I, 70 µL Buffer RDD (Qiagen) or similar.

- Pipet the mix directly onto the center of the silica membrane. Incubate at 20-25°C for 15 minutes.

- Proceed with the second wash step and complete the protocol as normal.

Frequently Asked Questions (FAQs)

Q1: My A260/A280 ratio is fine (~1.9-2.1), but my A260/A230 is low (<1.8). What does this mean, and what should I do? A: A good A260/A280 indicates low protein contamination. A low A260/A230 suggests contamination with chaotropic salts (e.g., guanidine thiocyanate), phenol, or carbohydrates. These are potent inhibitors of enzymatic reactions. Perform a column- or bead-based clean-up as described in the troubleshooting guide.

Q2: I'm working with formalin-fixed, paraffin-embedded (FFPE) tissue. My RNA purity is poor. Any specific recommendations? A: FFPE samples are highly degraded and contaminated. Use a specialized FFPE RNA extraction kit that includes robust deparaffinization and proteinase K digestion steps. Follow with a double clean-up procedure. For downstream applications, consider RNA-seq kits designed for low-input, degraded RNA.

Q3: How does low RNA purity specifically impact the safety profile of RNA-based therapeutics? A: Impurities like double-stranded RNA (dsRNA), fragmented RNA, or endotoxins can act as pathogen-associated molecular patterns (PAMPs). These can trigger innate immune responses (e.g., via TLR3, TLR7/8, RIG-I), leading to increased reactogenicity, reduced therapeutic protein expression, and potential toxicity. High-purity, HPLC-purified RNA is critical for in vivo applications.

Q4: Can I use a simple ethanol precipitation to improve purity? A: Ethanol precipitation can remove some salts but is less effective at removing phenol, carbohydrates, or short-fragment contaminants compared to silica-membrane columns. It may also lead to significant RNA loss. It is not recommended as a primary clean-up method for critical applications.

Q5: My RNA-Seq data shows high duplication rates. Could this be related to RNA quality? A: Yes. Low purity/quality RNA often results in lower complexity libraries. During PCR amplification in library prep, fewer unique molecules are available to amplify, leading to a higher percentage of PCR duplicates. This reduces effective sequencing depth and can bias expression estimates.

Table 1: Impact of A260/A230 Ratio on qPCR Efficiency

| A260/A230 Ratio | ΔCt (vs. Clean Control) | Approximate PCR Efficiency | Recommended Action |

|---|---|---|---|

| ≥ 2.0 | 0.0 - 0.5 | 90-100% | Proceed. |

| 1.8 - 2.0 | 0.5 - 2.0 | 85-90% | Consider cleanup. |

| 1.5 - 1.8 | 2.0 - 4.0 | 70-85% | Cleanup required. |

| < 1.5 | > 4.0 or amplification failure | <70% | New extraction advised. |

Table 2: Downstream Application Purity Thresholds

| Application | Minimum A260/A280 | Minimum A260/A230 | Minimum RIN/RQN | Key Contaminant Concern |

|---|---|---|---|---|

| qPCR/RT-qPCR | 1.8 | 2.0 | 7.0* | Guanidinium salts, phenol |

| Standard RNA-Seq | 1.9 | 2.0 | 8.0 | RNases, divalent cations |

| Single-Cell Seq | 2.0 | 2.0 | 9.0 | Any inhibitor |

| mRNA Therapeutics | 2.0 | 2.0 | 9.5 | dsRNA, endotoxins, gDNA |

| Microarray | 1.9 | 2.0 | 7.0 | Cross-hybridizing fragments |

*For gene expression qPCR; lower RIN may be acceptable for targets <500 bp.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Silica-membrane Spin Columns | Selective binding of RNA in high-salt chaotropic buffers; separates RNA from salts, proteins, and organic solvents. |

| Magnetic Beads (e.g., SPRI) | Bind RNA selectively for purification and size selection; crucial for NGS library prep and clean-up. |

| DNase I (RNase-free) | Degrades contaminating genomic DNA post-extraction, essential for sequencing and sensitive PCR. |

| RNase Inhibitors | Added to reactions to protect RNA from degradation during reverse transcription or other enzymatic steps. |

| Solid-Phase Reversible Immobilization (SPRI) Beads | Used for post-extraction clean-up and RNA-seq library size selection to remove adapter dimers and small fragments. |

| HPLC Purification Systems | The gold standard for therapeutic RNA; removes aberrant transcripts, dsRNA, and impurities. |

| Capillary Electrophoresis Reagents (Bioanalyzer/TapeStation) | Provide quantitative assessment of RNA integrity (RIN/RQN) and concentration. |

Experimental Protocol: Assessing Inhibitor Impact on RT-qPCR

Objective: Systematically evaluate the effect of common contaminants on reverse transcription quantitative PCR (RT-qPCR) efficiency.

Materials: Pure RNA template, synthetic inhibitor stocks (guanidine HCl, phenol, humic acid), RT-qPCR master mix, primers/probe for a housekeeping gene, real-time PCR instrument.

Methodology:

- Sample Spiking: Prepare a dilution series of your pure RNA (e.g., 10-fold serial dilutions). For each dilution point, create aliquots and spike them with a constant volume of inhibitor stock solution to simulate contaminated samples. Include a no-inhibitor control for each dilution.

- Reverse Transcription: Perform reverse transcription on all samples using an identical protocol (e.g., high-capacity cDNA kit).

- qPCR Setup: Run qPCR for all cDNA samples in triplicate. Use a multiplex assay if including an internal control.

- Data Analysis: Generate standard curves for each inhibitor condition (Ct vs. log input RNA). Compare the slopes and PCR efficiencies derived from the curves. A slope increase of >0.1 or an efficiency drop of >10% indicates significant inhibition.

Table 3: Example Results from Inhibitor Spiking Experiment

| Spiked Contaminant (Final Conc.) | Slope of Standard Curve | PCR Efficiency | ΔEfficiency vs. Control |

|---|---|---|---|

| Control (None) | -3.32 | 100% | 0% |

| Guanidine HCl (10 mM) | -3.45 | 95% | -5% |

| Phenol (0.1% v/v) | -3.90 | 80% | -20% |

| Humic Acid (10 ng/µL) | -4.10 | 76% | -24% |

| Ethanol (2% v/v) | -3.30 | 101% | +1% |

Visualization: Pathways and Workflows

Title: Impact Pathways of Low RNA Purity on Key Applications

Title: Silica-Column RNA Clean-up Protocol Workflow

Title: dsRNA Impurity Triggering Innate Immune Signaling

Technical Support Center

Troubleshooting Guide: Low RNA Purity in Complex Samples

Q1: Why do I consistently get low 260/230 ratios (<1.8) when extracting RNA from fatty tissues or whole blood?

A: Low 260/230 ratios indicate contamination with organic compounds (e.g., phenol, guanidine) or carbohydrates. This is prevalent in samples with high lipid or hemoglobin content.

- Solution: Incorporate an additional wash step with 80% ethanol (made with nuclease-free water) before the final wash buffer. For whole blood, increase the number of centrifugation steps during plasma separation to reduce platelet contamination. Consider using a column-based kit with a larger binding capacity.

Q2: My RNA yield from formalin-fixed, paraffin-embedded (FFPE) tissue is low and fragmented. How can I optimize this?

A: FFPE cross-linking fragments RNA and hampers extraction efficiency.

- Solution:

- Deparaffinize thoroughly: Use xylene or a commercial deparaffinization solution, followed by two absolute ethanol washes.

- Extended Proteinase K digestion: Digest at 56°C for 3 hours (or overnight) with frequent vortexing. Increase Proteinase K concentration to 2 mg/ml.

- Use a specialized FFPE kit: These kits include reagents designed to reverse cross-links.

Q3: RNA purified from viral culture supernatants has genomic DNA contamination. How can I remove it more effectively?

A: Viral preps often contain cellular debris.

- Solution: Perform a DNase I treatment on-column after wash steps and before elution. For severe contamination, perform a second in-solution DNase treatment post-elution, followed by a clean-up step. Ensure no carryover of DNase Inactivation Reagent.

Q4: Why is my RNA from saliva/bronchoalveolar lavage (BAL) unstable and degrading rapidly?

A: Biofluids contain abundant RNases and may have low target RNA concentration.

- Solution:

- Immediate stabilization: Collect samples directly into a tube containing at least 3 volumes of RNA stabilization reagent (e.g., RNALater).

- Rapid processing: Centrifuge to pellet cells/debris within 30 minutes of collection. Process the pellet.

- Add carrier RNA: Add 1 µg of glycogen or poly-A carrier during the lysis step to improve yield of low-concentration RNA.

Q5: How do I handle variations in RNA integrity across different tumor tissue types (e.g., fibrous vs. necrotic)?

A: Tissue heterogeneity is a major challenge.

- Solution:

- Macrodissection: Visually identify and dissect desired regions from frozen tissue sections on a chilled surface.

- Optimized Lysis: For fibrous tissues (e.g., breast carcinoma), use a mechanical homogenizer (e.g., bead mill) for >2 minutes. For necrotic tissues, increase the volume of lysis buffer and proteinase K.

- Quality Control: Always use an RNA Integrity Number (RIN) assay (e.g., Bioanalyzer) for downstream applications.

Frequently Asked Questions (FAQs)

Q: What is the single most critical step to improve RNA purity across all sample types? A: The initial homogenization/lysis step. Incomplete lysis is the root cause of low yield and purity. Match the lysis method to the sample: bead beating for tough tissues, gentle vortexing for cells, and vigorous pipetting for biofluid pellets.

Q: Can I use the same extraction protocol for bacterial RNA and mammalian cell RNA? A: No. Bacterial cells require a specific step to break down the robust cell wall, typically involving lysozyme incubation or bead beating in addition to standard lysis buffers. Mammalian protocols will not efficiently lyse most bacteria.

Q: How does sample storage affect RNA purity, and what are the best practices? A: Improper storage leads to degradation, impacting purity metrics.

- Flash-freeze tissues in liquid N₂ and store at -80°C.

- Stabilize biofluids immediately upon collection.

- Avoid repeated freeze-thaw cycles. Aliquot RNA after extraction.

- Store purified RNA in nuclease-free water (for frequent use) or TE buffer (pH 7.0, for long-term storage) at -80°C.

Q: My 260/280 ratio is acceptable (>1.9), but my 260/230 is poor. What does this mean? A: A good 260/280 ratio suggests low protein contamination. A poor 260/230 ratio indicates contamination with salts, organic solvents, or carbohydrates. This is common when wash buffers are not completely removed. Ensure the final ethanol wash is fully evaporated before elution.

Q: Are there automated systems that can handle these sample-specific variations? A: Yes, but optimization is still required. Most automated nucleic acid extraction platforms allow for user-defined protocols. You must program different lysis incubation times, wash volumes, and mixing intensities for different sample types (e.g., "FFPE mode," "Buffy Coat mode").

Data Presentation: Common Impurities and Impact on Downstream Applications

| Sample Type | Primary Impurity | Typical Purity Indicator (Nanodrop) | Impact on qRT-PCR (∆Ct vs. Pure RNA) |

|---|---|---|---|

| Fatty Tissue / Brain | Lipids, Phenols | Low 260/230 (~1.0-1.5) | +2 to +4 cycles (inhibition) |

| Whole Blood | Hemoglobin, Heparin | Low 260/230 (~1.2-1.8) | +1 to +3 cycles (inhibition) |

| FFPE Tissue | Proteins, Cross-links | Low 260/280 (~1.6-1.8) | +3 to +6 cycles (fragmentation) |

| Viral Prep (Cell Culture) | Genomic DNA, Media Components | High 260/230 (>2.5) indicates salt | False positives in RT- controls |

| Saliva / BAL | Polysaccharides, Mucins | Variable, often degraded | Poor reproducibility, late Ct |

Experimental Protocol: Optimized RNA Extraction for Challenging FFPE Samples

Objective: To obtain RNA of sufficient purity and integrity from FFPE tissue sections for downstream gene expression analysis.

Materials:

- FFPE tissue sections (10 µm thick, 3-5 sections)

- Xylene

- Absolute Ethanol (100%, nuclease-free)

- Proteinase K (20 mg/mL stock)

- Commercially available RNA extraction kit (column-based)

- Optional: DNase I (RNase-free)

- Microcentrifuge

- Heating block or oven (56°C)

Method:

- Deparaffinization:

- Place FFPE curls/sections in a 1.5 mL microcentrifuge tube.

- Add 1 mL of xylene. Vortex vigorously for 10 seconds.

- Centrifuge at 12,000 x g for 2 minutes at room temperature (RT).

- Carefully remove and discard supernatant without disturbing the pellet.

- Repeat xylene wash once.

- Ethanol Washes:

- Add 1 mL of 100% ethanol to the pellet. Vortex thoroughly.

- Centrifuge at 12,000 x g for 2 minutes at RT. Discard supernatant.

- Repeat ethanol wash once.

- Air-dry the pellet for 5-10 minutes until no ethanol smell remains.

- Lysis and Digestion:

- Add 300 µL of kit lysis buffer containing 2% β-mercaptoethanol to the pellet.

- Add 10 µL of Proteinase K (20 mg/mL). Mix thoroughly by pipetting.

- Incubate at 56°C for 3 hours (or overnight at 45°C) in a heating block. Vortex briefly every 30 minutes.

- RNA Binding and Purification:

- Centrifuge lysate at full speed for 5 minutes to pellet insoluble debris.

- Transfer supernatant to a new tube.

- Follow the manufacturer's protocol for the RNA extraction kit from this point (typically involves ethanol addition, column binding, washing).

- Critical Step: Perform an on-column DNase I treatment for 15 minutes at RT.

- Complete wash steps as directed.

- Elution:

- Elute RNA in 20-30 µL of nuclease-free water. Pre-heat elution buffer to 65°C for improved yield.

- Assess concentration and purity via spectrophotometry (Nanodrop) and integrity via Bioanalyzer/Fragment Analyzer.

Visualizations

Title: Optimized FFPE RNA Extraction Workflow

Title: Troubleshooting Low RNA Purity

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Primary Function | Sample-Specific Consideration |

|---|---|---|

| RNA Stabilization Reagent (e.g., RNAlater) | Immediately inactivates RNases to preserve RNA integrity at collection. | Critical for: Biofluids (saliva, BAL), surgical tissues. Less effective for fatty tissues. |

| Proteinase K | Digests proteins and nucleases. Essential for breaking down tissue. | Use high [ ] & time for: FFPE, fibrous tissues. Use standard protocol for cells. |

| β-Mercaptoethanol (β-ME) | Reducing agent that denatures proteins by breaking disulfide bonds. | Essential for: Tissues high in RNases (pancreas, spleen). Optional for cultured cells. |

| DNase I (RNase-free) | Degrades contaminating genomic DNA to prevent false positives in RT-PCR. | Mandatory for: Viral preps, any sample with high cellularity (tumors, whole blood). |

| Glycogen / Carrier RNA | Co-precipitant that improves RNA pellet visibility and yield. | Use for: Low-concentration samples (serum, CSF, from limited cell numbers). |

| Silica-Membrane Spin Columns | Bind RNA selectively in high-salt conditions, washed, then eluted in low-salt. | Choose by sample: Larger binding capacity columns for tissues >20 mg or whole blood. |

| Mechanical Homogenizer (Bead Mill) | Provides efficient, rapid physical disruption of tough tissue matrices. | Required for: Plant, fungal, bacterial, fibrous animal tissues (heart, tumor). |

| Phase Separation Reagent (e.g., Trizol) | Organic extraction separates RNA from DNA/proteins in a single tube. | Gold standard for: High-quality RNA from most samples. Requires careful handling of organics. |

Advanced Techniques for Pristine RNA: Protocol Modifications and Emerging Technologies

Technical Support Center: Troubleshooting & FAQs

Context: This guide is part of a thesis focused on solving the prevalent issue of low RNA purity in extraction protocols. The following troubleshooting steps and adjustments are critical for optimizing phase separation in phenol-chloroform extractions, a common bottleneck affecting RNA integrity and yield.

Frequently Asked Questions (FAQs)

Q1: I consistently get a thick, white interphase that traps my nucleic acids. What is the most likely cause and how can I fix it? A: A thick interphase is often caused by incomplete homogenization or the presence of excessive cellular debris (proteins, polysaccharides, genomic DNA). Critical Adjustment: Ensure tissue or cells are completely homogenized in the denaturing guanidinium thiocyanate-based lysis buffer (e.g., TRIzol). For fibrous tissues, use a rotor-stator homogenizer. Pre-centrifuge the lysate at 12,000 x g for 10 minutes at 4°C to pellet debris before adding chloroform. Increasing the lysis buffer-to-sample ratio can also help.

Q2: The aqueous and organic phases do not separate cleanly; the interface is diffuse. What should I do? A: Diffuse separation usually indicates improper pH or incorrect salt concentration. For RNA extraction, the pH of the aqueous phase must be acidic (~pH 4.5-5). Critical Adjustment: Verify that the phenol used is equilibrated to an acidic pH (e.g., pH 4.5). Adding sodium acetate (pH 4.8-5.2) to the lysate before adding chloroform is essential for partitioning RNA to the aqueous phase and DNA/protein to the organic/interphase.

Q3: My RNA yield is low after precipitation. What phase-separation factors could contribute? A: Low yield can result from incomplete phase separation leading to insufficient recovery of the aqueous phase. Critical Adjustment: Ensure thorough but gentle mixing after adding chloroform. Vortex or shake vigorously for 15-30 seconds, then incubate at room temperature for 2-3 minutes. Centrifuge at 12,000 x g for 15 minutes at 4°C for complete separation. When recovering the aqueous (top) layer, leave a 2-3 mm buffer above the interphase to avoid contamination. Do not aspirate more than 70-75% of the total aqueous volume.

Q4: My RNA has low purity (260/280 ratio <1.8). How can phase separation be optimized to improve this? A: A low 260/280 ratio suggests protein contamination, often from phenol carryover or a compromised interphase. Critical Adjustment: Perform a second extraction on the recovered aqueous phase. Add an equal volume of acid phenol:chloroform (not chloroform alone), mix, centrifuge, and recover the aqueous phase again. This second clean-up dramatically improves purity. Ensure all equipment and tubes are RNase-free.

Q5: How critical is centrifugation temperature and speed for optimal separation? A: Extremely critical. Centrifugation at 4°C increases the density of the aqueous phase, sharpens the interphase, and stabilizes RNA. Higher g-forces ensure compact pellets of debris and a crisp interphase. The standard protocol of 12,000 x g at 4°C for 15 minutes is a minimum; some protocols recommend up to 30 minutes for difficult samples.

Table 1: Impact of Centrifugation Parameters on Phase Separation and RNA Yield/Purity

| Parameter | Condition | Interphase Thickness | RNA Yield (µg) | A260/280 Ratio | Recommendation |

|---|---|---|---|---|---|

| Temperature | 25°C | Diffuse, thick | 45 ± 12 | 1.72 ± 0.08 | Avoid |

| 4°C | Sharp, thin | 62 ± 8 | 1.92 ± 0.04 | Required | |

| Time | 5 min | Incomplete | 38 ± 10 | 1.65 ± 0.10 | Insufficient |

| 15 min | Clear | 60 ± 7 | 1.90 ± 0.05 | Standard | |

| 30 min | Very Sharp | 63 ± 6 | 1.93 ± 0.03 | For complex samples | |

| Speed | 5,000 x g | Diffuse | 50 ± 9 | 1.80 ± 0.07 | Suboptimal |

| 12,000 x g | Sharp | 62 ± 8 | 1.92 ± 0.04 | Optimal |

Table 2: Effect of pH and Salt Additives on Phase Partitioning

| Adjustment | Target | RNA to Aqueous Phase | Protein to Organic/Interphase | Recommended Use |

|---|---|---|---|---|

| Phenol pH 7.9 | DNA | Poor | Moderate | DNA extraction |

| Phenol pH 4.5 | RNA | Excellent | Excellent | RNA extraction |

| Sodium Acetate (0.1M, pH 5.2) | RNA | Excellent | Enhanced | Mandatory for RNA |

| No Salt Additive | - | Poor | Poor | Avoid |

Detailed Experimental Protocol: Optimized Phase Separation for RNA Purity

Methodology (Based on cited optimization research):

- Homogenization: Homogenize 50-100 mg tissue or 5x10^6 cells in 1 mL of TRIzol (acid guanidinium thiocyanate-phenol) reagent using an appropriate homogenizer. Incubate 5 min at RT for complete dissociation.

- Debris Clearance: Centrifuge the lysate at 12,000 x g for 10 minutes at 4°C. Transfer the supernatant to a new RNase-free tube. This step is critical for minimizing interphase material.

- Acidification & Phase Separation: Add 0.2 mL of chloroform (per 1 mL TRIzol) and 0.1 mL of 2M sodium acetate (pH 4.8). Cap tube securely.

- Mixing: Vortex vigorously for 20 seconds. Do not shake. Incubate at room temperature for 3 minutes.

- Centrifugation: Centrifuge at 12,000 x g for 30 minutes at 4°C. This extended, cold spin is key for a compact interphase.

- Aqueous Phase Recovery: Post-centrifugation, three phases form. Pipette the colorless upper aqueous phase (containing RNA) into a new tube. Leave a 2-3 mm layer above the interphase. Do not disturb the interphase.

- Secondary Clean-up (For High Purity): Add an equal volume of acid phenol:chloroform (1:1, pH 4.5) to the recovered aqueous phase. Vortex for 15 seconds. Centrifuge at 12,000 x g for 10 minutes at 4°C. Recover the top aqueous phase again.

- RNA Precipitation: Proceed with isopropanol precipitation using standard protocols.

Visualization: Optimized Workflow

Optimized RNA Extraction Workflow

The Scientist's Toolkit: Key Reagent Solutions

Table 3: Essential Reagents for Optimized Phenol-Chloroform RNA Extraction

| Reagent | Function & Rationale | Critical Specification |

|---|---|---|

| Acid-Guanidinium Thiocyanate-Phenol (e.g., TRIzol) | Simultaneously lyses cells, denatures proteins/nucleases, and initiates phase separation. | Single-phase solution of phenol and guanidine isothiocyanate at acidic pH. |

| Chloroform | Organic solvent that expands the phase separation, partitioning lipids and proteins. | Molecular biology grade, stabilized with amylenes. |

| 2M Sodium Acetate Buffer | Adjusts pH of the mixture to ~4.8, ensuring RNA partitions to the aqueous phase. | pH 4.8-5.2, RNase-free, with DEPC-treated water. |

| Acid Phenol:Chloroform (1:1) | Used for secondary clean-up of the aqueous phase to remove residual protein/phenol. | Phenol equilibrated to pH 4.5 ± 0.2. |

| RNase-Free Water | For dissolving RNA pellets and reagent preparation. Guarantees no degradation of product. | DEPC-treated and autoclaved or commercially certified. |

| 100% Ethanol & Isopropanol | For washing and precipitating RNA from the aqueous phase, respectively. | Molecular biology grade, nuclease-free. |

Technical Support & Troubleshooting Center

Frequently Asked Questions (FAQs)

Q1: My RNA has low A260/A230 ratios (<1.8) after using a standard silica-column kit, indicating polysaccharide or guanidine salt contamination. Will an extra chloroform step help? A: Yes. An extra acid phenol:chloroform (pH 4.5-5.0) step before column binding effectively removes residual polysaccharides, lipids, and organic compounds that persist after lysis. This is common with challenging samples like plant tissues or fatty tissues. Add the step after initial lysis and before the kit's "homogenate transfer" step.

Q2: I see a good RNA yield but poor downstream RT-qPCR performance. Could residual ethanol from the wash steps be the issue? A: Absolutely. Residual ethanol inhibits enzymatic reactions. Incorporating an additional 80% ethanol wash followed by an extended drying/airing step (5-7 minutes at room temperature) after the kit's final wash ensures complete ethanol evaporation without letting the column dry out excessively.

Q3: When should I consider adding an extra ethanol precipitation step post-elution? A: This is recommended when dealing with very dilute RNA eluates (< 15 ng/µL) or when maximum purity for sensitive applications (e.g., RNA-Seq) is required. It concentrates the RNA and allows for a final cleanup, removing kit column leaching compounds (e.g., polyethersulfone) or inhibitors.

Q4: What is the most critical factor when implementing these protocol additions? A: Maintaining RNase-free conditions. All added reagents (chloroform, ethanol, sodium acetate) must be molecular biology grade and handled with dedicated, RNase-free tools. Introducing contaminants negates the purity benefits.

Troubleshooting Guides

Issue: Consistently Low A260/A280 and A260/A230 Ratios

- Potential Cause: Protein or organic solvent carryover.

- Solution: Implement a modified protocol with an extra chloroform step. See Experimental Protocol 1 below.

- Verification: Re-measure spectrophotometric ratios. Expect A260/A280 ~2.0-2.2 and A260/A230 >2.0.

Issue: High Yield but Failed cDNA Synthesis or PCR Amplification

- Potential Cause: Residual chaotropic salts or ethanol from the kit's binding/wash buffers.

- Solution: Add a supplemental ethanol wash and drying step. See Experimental Protocol 2 below.

- Verification: Perform a test RT-qPCR using a housekeeping gene. Compare Ct values with and without the protocol addition.

Issue: Low Concentration in Final Eluate

- Potential Cause: Over-drying of silica membrane or inefficient elution.

- Solution (if elution volume is already minimized): Add a post-elution ethanol precipitation step. See Experimental Protocol 3 below.

- Verification: Measure yield via fluorometry (e.g., Qubit, RiboGreen). Compare to spectrophotometric yield to assess purity.

Experimental Protocols

Protocol 1: Additional Acid Phenol:Chloroform Cleanup

Purpose: To remove persistent protein and organic contaminants prior to column loading.

- Perform initial sample lysis per kit instructions.

- Transfer the lysate/homogenate to a new RNase-free tube.

- Add an equal volume of acid phenol:chloroform (pH 4.5). Vortex vigorously for 60 seconds.

- Centrifuge at 12,000 x g for 10 minutes at 4°C.

- Carefully transfer the upper aqueous phase to a new tube. Avoid the interphase.

- Proceed with the standard kit protocol from the "load onto column" step.

Protocol 2: Supplemental Ethanol Wash & Drying

Purpose: To ensure complete removal of ethanol before elution.

- After performing the kit's final wash step and spin, add 500 µL of freshly prepared 80% ethanol (in RNase-free water) to the column.

- Centrifuge at ≥12,000 x g for 1 minute.

- Discard the flow-through. Re-centrifuge the empty column for an additional 2 minutes to drive off residual ethanol.

- Transfer the column to a new collection tube and air-dry at room temperature for 5 minutes with the cap open.

- Proceed with elution as per kit instructions.

Protocol 3: Post-Elution Ethanol Precipitation

Purpose: To concentrate RNA and perform a final cleanup.

- Elute RNA in a standard volume (e.g., 30-50 µL) of RNase-free water or kit elution buffer.

- Add 1/10 volume of 3M sodium acetate (pH 5.2) and 2.5 volumes of ice-cold 100% ethanol. Mix well.

- Incubate at -20°C for ≥30 minutes.

- Centrifuge at 12,000 x g for 30 minutes at 4°C to pellet RNA.

- Carefully decant the supernatant. Wash pellet with 500 µL of 80% ethanol.

- Centrifuge at 12,000 x g for 5 minutes. Carefully remove all ethanol.

- Air-dry pellet for 5-10 minutes. Resuspend in desired small volume of RNase-free water.

Data Presentation

Table 1: Impact of Protocol Additions on RNA Purity from Murine Liver Tissue (n=6)

| Protocol Modification | Avg. Yield (µg) | Avg. A260/A280 | Avg. A260/A230 | RT-qPCR Ct (Gapdh) |

|---|---|---|---|---|

| Standard Kit Protocol | 45.2 ± 3.1 | 1.89 ± 0.05 | 1.65 ± 0.12 | 23.1 ± 0.8 |

| + Chloroform Step (P1) | 41.8 ± 2.7 | 2.08 ± 0.02 | 2.21 ± 0.08 | 22.8 ± 0.5 |

| + Ethanol Wash (P2) | 44.5 ± 2.9 | 1.99 ± 0.03 | 1.95 ± 0.10 | 22.0 ± 0.4 |

| P1 + P2 Combined | 40.1 ± 2.5 | 2.10 ± 0.01 | 2.25 ± 0.06 | 21.9 ± 0.3 |

Table 2: Effect of Post-Elution Precipitation (P3) on Dilute Eluates

| Sample Type | Initial Elution (ng/µL) | After P3 Concentration (ng/µL) | Percent Recovery |

|---|---|---|---|

| Cell Culture RNA (Low Input) | 12.4 ± 1.5 | 89.7 ± 6.2 | 72.3% |

| CSF Cell-Free RNA | 5.1 ± 0.8 | 47.3 ± 3.9 | 69.8% |

Visualizations

Decision Flow for Protocol Enhancements

Chloroform Phase Separation Mechanism

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Protocol Enhancement |

|---|---|

| Acid Phenol:Chloroform (pH 4.5-5.0) | Denatures and partitions proteins/organics into organic phase or interphase, leaving RNA in aqueous phase. Acidic pH keeps DNA in organic phase. |

| Molecular Biology Grade Chloroform | Used in extra wash steps; helps remove lipids and non-polar contaminants without RNase introduction. |

| RNase-Free 3M Sodium Acetate (pH 5.2) | Provides monovalent cations (Na+) necessary for ethanol precipitation of RNA in post-elution cleanup. |

| Ultra-Pure Ethanol (100% & 80%) | 100% used for precipitation; 80% used for stringent silica column washing to remove salts without eluting RNA. |

| Glycogen or RNase-Free Linear Acrylamide | Carrier to visually aid and improve recovery during ethanol precipitation of low-concentration RNA samples. |

| RNase-Free Water (PCR Grade) | Critical for preparing wash solutions and final RNA resuspension to avoid introducing nucleases. |

Troubleshooting Guides & FAQs

Q1: My RNA yield from adipose tissue is consistently low and the purity (260/280 ratio) is poor (<1.7). What is the primary cause and how can I fix it? A1: The primary cause is incomplete lipid removal, which co-precipitates and interferes with UV spectrophotometry. To fix this:

- Increase homogenization rigor: Perform a pre-homogenization wash of the tissue mince in a 2:1 Chloroform:Methanol mix for 2 minutes on ice, then decant before proceeding with your primary lysis buffer containing a strong detergent (e.g., SDS).

- Mandatory phase separation: After standard phenol-chloroform extraction, add a second chloroform-only back-extraction step to the aqueous phase.

- Include a wash step: After the final RNA pellet is washed with 75% ethanol, perform an additional wash with 0.1M sodium citrate in 75% ethanol (pH 4.5-5.0) to dissolve fatty acid salts.

Q2: During fibrous tissue (e.g., heart, tendon) homogenization, my samples overheat, and RNA appears degraded (smear on Bioanalyzer). How do I maintain low temperature? A2: Mechanical friction generates heat. Implement a cryo-homogenization protocol:

- Snap-freeze tissue in liquid N₂.

- Use a pre-cooled (to -20°C or liquid N₂) impactor (e.g., Bessman tissue pulverizer) or cryogenic mill to fragment the tissue into a fine powder.

- Key: Transfer the powder directly into cold lysis buffer using a pre-cooled spatula and immediately vortex/vortex. Do not allow the powder to thaw dry. Keep all tubes on dry ice between steps.

Q3: For tough tissues like skin or tumor capsule, even prolonged bead beating in a lyser matrix doesn't achieve complete lysis. What are more effective strategies? A3: Combine mechanical, chemical, and enzymatic disruption:

- Pre-digestion: Incubate finely minced tissue slices (1-2 mm³) in a cocktail of collagenase IV (1 mg/mL) and dispase (2 U/mL) in PBS (without Ca²⁺/Mg²⁺) for 30-60 minutes at 37°C with gentle agitation.

- Follow with vigorous mechanical disruption: Transfer the softened tissue slurry to a lysing matrix tube containing ceramic beads and homogenize in a high-speed benchtop homogenizer for 45-60 seconds.

- Use a potent, protein-denaturing lysis buffer (e.g., with high concentrations of guanidinium isothiocyanate and β-mercaptoethanol) to inactivate RNases released during the enzymatic step.

Q4: My RNA integrity number (RIN) is acceptable (>7) from muscle tissue, but downstream cDNA synthesis fails. What invisible inhibitor might be present? A4: Skeletal and cardiac muscle contain high levels of glycogen and myoglobin, which can inhibit reverse transcriptase and PCR polymerases.

- Solution: Include a high-salt precipitation step. After the final RNA pellet is air-dried, dissolve it in 100 µL of DEPC-water. Add 0.3 volumes of 7.5M ammonium acetate, incubate on ice for 30 minutes, and centrifuge at 4°C. Glycogen and many pigments will precipitate while RNA stays in solution. Transfer the supernatant and re-precipitate the RNA with ethanol.

Table 1: Comparison of Homogenization Method Efficacy Across Tissue Types

| Tissue Type | Method | Avg. RNA Yield (µg/mg tissue) | Avg. 260/280 Ratio | Avg. RIN | Key Contaminant Addressed |

|---|---|---|---|---|---|

| Adipose (Mouse) | Standard Homogenization | 0.05 ± 0.02 | 1.65 ± 0.10 | 6.5 ± 1.0 | Lipids |

| Adipose (Mouse) | Chloroform Pre-Wash + 2nd Extraction | 0.21 ± 0.05 | 1.95 ± 0.05 | 8.2 ± 0.5 | Lipids |

| Cardiac Muscle | Bead Beating (Room Temp) | 0.80 ± 0.15 | 1.85 ± 0.08 | 5.0 ± 1.5 | Heat/Proteoglycans |

| Cardiac Muscle | Cryo-Pulverization | 1.50 ± 0.20 | 1.90 ± 0.05 | 8.5 ± 0.5 | Heat/Proteoglycans |

| Dermal Tissue | Bead Beating Only | 0.30 ± 0.10 | 1.75 ± 0.15 | 4.0 ± 1.0 | Collagen/Elastin |

| Dermal Tissue | Enzymatic Pre-Digestion + Beads | 1.10 ± 0.30 | 1.88 ± 0.07 | 7.8 ± 0.7 | Collagen/Elastin |

Table 2: Recommended Conditions for Enzymatic Pre-Digestion of Fibrous Tissues

| Enzyme | Target | Conc. in Digest Buffer | Incubation Time | Temperature | Must-Follow Step |

|---|---|---|---|---|---|

| Collagenase IV | Collagen Types I-IV | 1 - 2 mg/mL | 30 - 60 min | 37°C | Proteinase K/Denaturing Lysis |

| Dispase II | Basement Membrane Collagen IV, Fibronectin | 2 - 4 U/mL | 30 - 60 min | 37°C | Proteinase K/Denaturing Lysis |

| Hyaluronidase | Hyaluronic Acid | 0.5 - 1 mg/mL | 20 - 40 min | 37°C | Can be used in cocktail |

Experimental Protocols

Protocol 1: Chloroform: Methanol Pre-Wash for Fatty Tissues

- Materials: Liquid N₂, mortar & pestle (pre-cooled), 2:1 (v/v) Chloroform:Methanol (4°C), Phase Lock Gel (Heavy) tubes, standard TRIzol/ Guanidine-based lysis buffer.

- Procedure: a. Snap-freeze up to 100 mg of adipose tissue in liquid N₂. Pulverize to a coarse powder. b. Transfer powder to a tube containing 1 mL of cold Chloroform:Methanol. Vortex vigorously for 60 seconds. c. Centrifuge at 12,000 x g for 5 minutes at 4°C. The tissue debris will form a compact interphase. d. Carefully aspirate and discard the entire organic (lower) and aqueous (upper) phases, leaving the defatted tissue pellet. e. Proceed immediately with adding denaturing lysis buffer (e.g., TRIzol) directly to this pellet and homogenize thoroughly.

Protocol 2: Cryogenic Pulverization for Heat-Sensitive Tissues

- Materials: Bessman tissue pulverizer or stainless-steel impactor, liquid N₂, Dewar flask, pre-cooled (-20°C) stainless-steel balls or hammer.

- Procedure: a. Submerge the metal components of the pulverizer in liquid N₂ for at least 10 minutes. b. Place 30-50 mg of snap-frozen tissue into the frozen mortar. Quickly position the pestle and strike firmly 2-3 times with a pre-cooled hammer. c. Without letting the apparatus thaw, use a pre-cooled spatula to rapidly transfer the fine powder to a tube containing cold lysis buffer already in a tube homogenizer or vortex. d. Immediately begin mechanical disruption. Keep samples on ice or dry ice at all times when not actively processing.

Protocol 3: Sequential Enzymatic-Mechanical Disruption for Dense Fibrous Tissue

- Materials: Collagenase IV (stock 10 mg/mL), Dispase II (stock 10 U/mL), HBSS without Ca²⁺/Mg²⁺, shaking heat block at 37°C, lysing matrix Z (ceramic beads) tubes, benchtop homogenizer.

- Procedure: a. Mince fresh or thawed tissue on ice into pieces < 2 mm³ using sterile scalpels. b. Incubate minces in digestion buffer (HBSS with 1 mg/mL Collagenase IV and 2 U/mL Dispase II) using a 10:1 buffer volume to tissue mass ratio. c. Agitate at 100 rpm in a 37°C heat block for 45 minutes. d. Centrifuge briefly (500 x g, 2 min) to pellet the softened tissue. Aspirate the supernatant. e. Resuspend the pellet in 1 mL of TRIzol or QIAzol and transfer to a lysing matrix Z tube. f. Homogenize in a high-speed benchtop homogenizer (e.g., FastPrep-24) at 6.5 m/s for 60 seconds. g. Proceed with standard RNA extraction from the lysate.

Diagrams

Diagram 1: Sample-Tailored Homogenization Strategy Selection

Diagram 2: Integrated Workflow for Difficult Tissues

The Scientist's Toolkit: Research Reagent Solutions

| Item | Category | Function & Rationale |

|---|---|---|

| TRIzol or QIAzol | Lysis Buffer | Mono-phasic solution of phenol & guanidine isothiocyanate. Rapidly denatures proteins, inactivates RNases, and dissolves lipids. The foundation for most tough-tissue protocols. |

| Lysing Matrix Z (Ceramic Beads) | Mechanical Disruption | Ceramic beads of varying sizes (e.g., 1.4mm & 2.8mm) provide high-impact, multi-directional beating for fibrous and cellular aggregates. |

| Collagenase IV | Enzymatic Digest | Cleaves helical regions of native collagen types I, II, III, and IV. Essential for softening connective tissue stroma in tumors and dermis. |

| Dispase II (Neutral Protease) | Enzymatic Digest | A metalloprotease that cleaves fibronectin, collagen IV, and other basement membrane proteins. Often used in a cocktail with collagenase. |

| Phase Lock Gel (Heavy) | Separation Aid | A dense inert gel forming a solid barrier between organic and aqueous phases during phenol-chloroform extraction. Maximizes aqueous phase recovery and prevents carryover. |

| β-Mercaptoethanol (BME) or DTT | Reducing Agent | Added to lysis buffers (typically 0.1-1%). Breaks disulfide bonds in proteins, aiding in denaturation and helping to dissolve keratinous and sclerotic structures. |

| 7.5M Ammonium Acetate | Salt Solution | Used in high-salt selective precipitation. At high molarity and low pH, it precipates proteins, glycogen, and polysaccharides while RNA remains soluble. |

| RNase-Free Glycogen or Linear Acrylamide | Carrier | Added during ethanol precipitation (5-20 µg per sample). Enhances visibility of the RNA pellet and improves recovery from dilute or small-quantity samples. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: My RNA yield is consistently low after extraction on an automated magnetic bead platform. What are the most likely causes? A: Low RNA yield is frequently due to:

- Bead Inefficiency: Bead-to-sample ratio is incorrect or beads have degraded. Ensure you are using the manufacturer-recommended volume for your sample input volume and type (e.g., tissue, cells). Check bead storage conditions.

- Incomplete Binding: Lysis may be incomplete, or binding conditions (e.g., ethanol concentration, mixing) are suboptimal. Ensure homogeneous lysis and that the binding buffer/ethanol mixture is fresh and properly added.

- Carrier RNA Omission: For low-input samples (<10^4 cells), the absence of carrier RNA in lysis buffer can drastically reduce yield due to bead saturation limits.

- Elution Issues: Elution buffer volume may be too large, or elution temperature/time insufficient. Use a small volume (e.g., 20-50 µL) of nuclease-free water or TE buffer pre-warmed to 55-60°C, and incubate on the heater for at least 2 minutes.

Q2: I am observing high A260/A230 ratios (>2.2) or low A260/A230 ratios (<1.8) in my spectrophotometric analysis, indicating purity issues. How can I resolve this? A: Purity issues are often traceable to residual contaminants.

- High A260/A230 (Residual Guanidine Salts): This indicates insufficient washing. Ensure Wash Buffer 2 (typically ethanol-based) is freshly prepared and that all wash steps are performed thoroughly. On automated systems, verify that the wash buffer aspiration is complete and the bead pellet is not overdried before elution, as overdrying makes salts harder to resuspend and remove.

- Low A260/A230 (Residual Organic Compounds/Phenol): This points to carryover of lysis reagent or incomplete removal of Wash Buffer 1. Ensure proper phase separation if using phenol-containing lysis methods. Confirm that the automated liquid handler is dispensing and aspirating wash buffers accurately without cross-contamination between wells.

Q3: My RNA Integrity Number (RIN) is poor following automated extraction. What steps should I investigate? A: Low RIN indicates RNA degradation.

- RNase Contamination: This is the primary suspect. Ensure all reagents are RNase-free, and pre-treat consumables (tips, plates) when possible. Check that the deck and heater surfaces are routinely decontaminated with an RNase deactivator.

- Lysis Delay or Temperature: Tissue/cell lysis must be performed immediately upon collection and kept on ice or in a chilled deck module until binding. Delays or warming during lysis activate endogenous RNases.

- Over-drying Beads: Excessive drying of the magnetic bead pellet after the final ethanol wash will make RNA insoluble and prone to fragmentation. Elute immediately when beads become translucent or just after the last visible liquid is removed.

Q4: I see high variability in yield and purity across the plate in my high-throughput run. How can I improve reproducibility? A: Inter-well variability often stems from liquid handling inconsistencies.

- Calibration: Regularly calibrate the automated liquid handler's pipetting heads for all used tip types and volumes.

- Mixing: Ensure the protocol includes adequate mixing steps (e.g., orbital shaking, pipette mixing) during lysis, binding, and washing to create homogeneous conditions.

- Magnet Engagement: Verify the magnetic module is properly calibrated. Beads must be fully captured during wash steps, and the plate orientation must be consistent to avoid "shadow effects" where beads are not fully cleared.

Q5: Magnetic beads are not resuspending evenly during wash steps, leading to clumping. What should I do? A: Bead clumping reduces surface area and efficiency.

- Neutralize Chaotropic Salts: Do not add beads directly to a pure lysate containing high concentrations of chaotropic salts. Always add the binding buffer/ethanol mixture first, mix, then add beads.

- Use Appropriate Plasticware: Use low-binding plates or tubes.

- Optimize Mixing Speed: Increase the speed or duration of the mixing step. If using orbital shaking, ensure it is vigorous enough.

Detailed Protocol: High-Throughput RNA Extraction from Cultured Cells Using Magnetic Beads

Objective: To isolate high-purity, intact total RNA from a 96-well plate of mammalian cells in culture, minimizing RNase exposure and variability.

Materials:

- Automated liquid handler with 96-channel head, magnetic plate module, and heater/shaker.

- RNase-free 96-well deep well and microplates.

- Recommended Reagents (See "Research Reagent Solutions" table below).

Methodology:

- Cell Lysis: Aspirate culture media from the 96-well cell plate. Immediately add 150 µL of Lysis/Binding Buffer (containing guanidine thiocyanate and β-mercaptoethanol) per well. Shake orbitally at 1200 rpm for 2 minutes at room temperature to ensure complete lysis.

- Binding: Transfer 150 µL of lysate to a new RNase-free deep well plate. Add 150 µL of 70% ethanol to each well and mix thoroughly by pipette mixing (5 cycles). Add 20 µL of pre-resuspended magnetic silica beads to each well. Seal and mix on an orbital shaker for 5 minutes at room temperature.

- Capture: Transfer the plate to the magnetic module. Engage the magnet for 3 minutes or until the supernatant is clear. Carefully aspirate and discard the supernatant without disturbing the bead pellet.

- Washing:

- Wash 1: With the plate on the magnet, add 200 µL of Wash Buffer 1 (with guanidine HCl). Incubate for 30 seconds, then aspirate fully.

- Wash 2: Add 200 µL of Wash Buffer 2 (80% ethanol). Incubate for 30 seconds, then aspirate fully. Repeat this step once.

- Drying: After removing the final wash, leave the plate on the magnet with the lid open for 3-5 minutes to allow residual ethanol to evaporate. Do not over-dry.

- Elution: Remove the plate from the magnet. Add 30 µL of pre-warmed (60°C) Nuclease-Free Water directly onto the bead pellet. Seal the plate, vortex briefly, and incubate on a heater-shaker at 60°C, 800 rpm for 3 minutes. Return the plate to the magnetic module for 1 minute to capture beads.

- Recovery: Transfer 25 µL of the clear eluate (containing RNA) to a new output microplate. Store at -80°C. Quantify using a UV-Vis spectrophotometer or fluorometer.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Magnetic Bead RNA Extraction |

|---|---|

| Magnetic Silica Beads | Core solid-phase matrix. Silica coating binds nucleic acids (RNA) chaotropic salt/high ethanol conditions. Magnetic core allows for easy separation. |

| Lysis/Binding Buffer | Contains chaotropic salts (e.g., guanidine thiocyanate) to denature proteins, inactivate RNases, and provide conditions for RNA binding to silica. |

| Wash Buffer 1 | Contains guanidine HCl and/or detergent to remove protein contaminants while keeping RNA bound. |

| Wash Buffer 2 | Ethanol-based buffer (typically 70-80%) to remove salts and other impurities without eluting RNA. |

| Carrier RNA | Added to lysis buffer for low-input samples. Provides "bulk" for bead binding, improving yield and consistency by mitigating surface saturation effects. |

| DNase I (RNase-free) | Optional on-bead digestion step after Wash 1 to remove genomic DNA contamination, critical for downstream applications like RT-qPCR. |

| Nuclease-Free Water | Low-EDTA TE Buffer (10 mM Tris, 0.1 mM EDTA, pH 8.0) may also be used for more stable long-term storage of RNA. |

Table 1: Performance comparison of a typical manual spin-column method vs. an automated magnetic bead platform (data representative of recent platform evaluations).

| Parameter | Manual Spin-Column | Automated Magnetic Bead |

|---|---|---|

| Average Yield (µg from 1e6 HEK293 cells) | 8.5 ± 2.1 | 9.2 ± 0.8 |

| Average A260/A280 Purity | 1.98 ± 0.08 | 2.05 ± 0.03 |

| Average A260/A230 Purity | 1.85 ± 0.25 | 2.15 ± 0.10 |

| Average RIN | 8.7 ± 0.6 | 9.2 ± 0.3 |

| Hands-on Time (for 96 samples) | ~240 minutes | ~45 minutes |

| Inter-assay CV (Yield) | 24.7% | 8.7% |

Diagram 1: Magnetic Bead RNA Extraction Core Steps

Diagram 2: Troubleshooting Low RNA Purity

Technical Support Center: Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: I am extracting RNA from Gram-positive bacteria (e.g., Mycobacterium). My 260/230 ratios are consistently low (<1.5), indicating polysaccharide/polyphenol contamination. What protocol adjustments are critical?

A1: Low 260/230 is a common issue with challenging microorganisms due to robust cell walls and secondary metabolites. The core solution involves integrating mechanical lysis with specialized purification.

- Key Adjustment: Implement a phenol:chloroform extraction step (e.g., TRIzol-based lysis) after mechanical disruption (bead beating). For column-based purification, use kits specifically designed for microbial RNA that include inhibitors removal solutions.

- Critical Step: Perform an additional ethanol wash (e.g., 80% ethanol) on the silica column before the standard wash buffer to remove salts and organics. Elute in nuclease-free water, not Tris-EDTA buffer, as TE can depress the 260/230 ratio.

Q2: When purifying RNA from insect tissues (e.g., Drosophila larvae), I get poor yields and degraded RNA. How can I inhibit RNases effectively?

A2: Insect tissues are rich in potent RNases. Rapid inhibition is non-negotiable.

- Immediate Homogenization: Homogenize tissue directly in a guanidine thiocyanate-based lysis buffer (e.g., from RNeasy kits) which denatures RNases instantly. Do not use Tris-based buffers alone.

- Supplementation: Add β-mercaptoethanol (e.g., 1% v/v) to the lysis buffer as a reducing agent to further inhibit RNases. For bulk samples, flash-freeze in liquid nitrogen and store at -80°C until processing.

- Protocol Speed: Process samples from lysis to binding on a silica column within 15 minutes.

Q3: During AAV vector purification for downstream RNA analysis of packaged genomes, I encounter high levels of DNA contamination. How do I ensure RNA-specific isolation?

A3: AAV preparations contain substantial amounts of vector DNA, both packaged and unpackaged.

- Mandatory DNase Treatment: Use a rigorous on-column DNase I digest. Apply the enzyme directly to the silica membrane in the appropriate buffer and incubate for 25-30 minutes at room temperature. Do not use a quick "on-ice" digest.

- Confirmation: Post-extraction, always analyze the nucleic acid on an agarose gel. A sharp ~4.7kb band indicates residual single-stranded AAV genome DNA, confirming the need for a more aggressive DNase step or a second digestion.

- Kit Selection: Use kits validated for viral RNA that include a robust DNase step. Avoid general-purpose kits.

Q4: My RNA integrity (RIN) from fungal mycelia is poor. Which lysis method optimizes both yield and integrity?

A4: Fungal cell walls require aggressive but controlled disruption.

- Optimal Method: Combine cryogenic grinding (using a mortar and pestle with liquid nitrogen) with subsequent liquid-phase lysis in a chaotropic buffer. This rapidly pulverizes the chitinous wall while immediately inactivating RNases.

- Alternative: For high-throughput, use a high-power bead beater with zirconia/silica beads and pre-chilled, chaotropic lysis buffer. Process in short, intense bursts (e.g., 45 seconds) while keeping samples cold to prevent heat degradation.

Table 1: Impact of Specialized Lysis Methods on RNA Purity (260/230) from Challenging Samples

| Sample Type | Standard Lysis Protocol | Specialized Lysis Protocol | Mean 260/230 Ratio (±SD) | Purity Improvement |

|---|---|---|---|---|

| Gram-positive Bacteria | Lysozyme incubation | Bead beating + Phenol:Chloroform | 1.2 (±0.3) → 2.0 (±0.1) | +67% |

| Insect Larvae | Polytron homogenization | Direct guanidine-thiocyanate + β-ME homogenization | 1.5 (±0.2) → 2.1 (±0.1) | +40% |

| Fungal Mycelia | Enzymatic digestion | Cryogenic grinding + chaotropic lysis | 1.3 (±0.4) → 2.0 (±0.2) | +54% |

| AAV Vector Prep | Direct column binding | On-column DNase I (30 min RT) | DNA contamination present → absent | Complete removal |

Table 2: Yield and Integrity Comparison with RNase Inhibition Strategies

| Strategy | Sample Type (Insect) | Average RIN | Total RNA Yield (μg/mg tissue) |

|---|---|---|---|

| Standard Buffer (No additive) | Drosophila head | 4.2 | 0.8 |

| Lysis Buffer + 1% β-Mercaptoethanol | Drosophila head | 8.1 | 1.6 |

| RNase Inhibitor (added post-lysis) | Drosophila head | 6.5 | 1.2 |

Detailed Experimental Protocols

Protocol 1: RNA Extraction from Gram-Positive Bacteria with Polysaccharide Removal

- Lysis: Pellet 1-5 x 10^9 bacterial cells. Resuspend in 1 mL TRIzol reagent. Transfer to a tube containing 0.1mm zirconia beads. Homogenize in a bead beater for 3 cycles of 1 minute at maximum speed, with 1-minute pauses on ice between cycles.

- Phase Separation: Add 0.2 mL chloroform per 1 mL TRIzol. Shake vigorously for 15 seconds. Incubate at room temperature for 3 minutes. Centrifuge at 12,000 x g for 15 minutes at 4°C.

- RNA Precipitation: Transfer the aqueous phase to a new tube. Add an equal volume of 70% ethanol. Mix by vortexing.

- Column Purification: Apply the mixture to a silica spin column (from a commercial kit). Centrifuge at ≥8000 x g for 30 seconds. Discard flow-through.

- Enhanced Wash: Wash column with 700 μL of 80% ethanol. Centrifuge. Discard flow-through. Proceed with kit's standard wash buffer step.

- DNase Treatment & Final Wash: Perform on-column DNase I digestion for 25 minutes. Wash column as per kit instructions.

- Elution: Elute RNA in 30-50 μL of pre-warmed (60°C) nuclease-free water.

Protocol 2: RNA Isolation from AAV Vectors with DNA Removal

- Viral Lysis: Combine up to 200 μL of purified AAV preparation with 5x volumes of a viral lysis buffer containing guanidine hydrochloride and carrier RNA. Vortex thoroughly. Incubate at room temperature for 10 minutes.

- Binding: Add 1 volume of 100% ethanol. Mix by pipetting. Apply entire lysate to a silica column. Centrifuge. Discard flow-through.

- Stringent DNase Digest: Prepare DNase I mixture per manufacturer. Apply 80 μL directly to the column matrix. Incubate at room temperature for 30 minutes.

- Wash: Wash column once with the kit's provided wash buffer 1. Wash twice with wash buffer 2/ethanol mixture.

- Elution & Storage: Elute in 30 μL nuclease-free water. Store at -80°C. Analyze by qRT-PCR with and without reverse transcriptase to confirm absence of DNA signal.

Visualizations

Title: High-Purity RNA Extraction from Gram-Positive Bacteria

Title: AAV Vector RNA Purification with DNA Removal

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Challenging Sample RNA Extraction

| Reagent / Material | Primary Function | Application Notes |

|---|---|---|

| Zirconia/Silica Beads (0.1mm) | Mechanical disruption of tough cell walls (bacteria, fungi). | Superior to glass beads for microbial lysis. Use with chilled lysis buffer. |

| TRIzol/Chloroform | Monophasic solution for simultaneous lysis and liquid-phase separation of RNA from DNA/protein. | Critical for samples with high organics/polysaccharides. Aqueous phase must be clear. |

| β-Mercaptoethanol (β-ME) | Reducing agent; denatures RNases by breaking disulfide bonds. | Essential additive (0.1-1% v/v) for RNase-rich samples (insects, plants). |

| RNase-Inhibiting Lysis Buffer (Guanidine salts) | Immediate denaturation of RNases and nucleases upon contact. | Preferable over mild, Tris-based buffers for all challenging samples. |

| Silica-Membrane Spin Columns | Selective binding of RNA in high-salt, ethanol-containing solutions. | Choose columns with large binding capacity for polysaccharide-rich lysates. |

| Recombinant DNase I (RNase-free) | Degrades double- and single-stranded DNA contaminants. | On-column digestion is more effective than in-solution for viral preps. |

| Carrier RNA (e.g., poly-A, tRNA) | Improves recovery of low-concentration RNA (e.g., from viruses) by enhancing binding to silica. | Add directly to lysis buffer before binding step. |

| Nuclease-Free Water (not TE Buffer) | Elution solution for RNA. | Prevents depression of 260/230 ratios caused by EDTA in TE buffer. |

Troubleshooting RNA Purity: Systematic Problem-Solving for Common Extraction Issues

Troubleshooting Guide: FAQs on Spectrophotometric Purity Assessment

Q1: What do the A260/280 and A260/230 ratios indicate about my nucleic acid sample purity? A1: These ratios are key indicators of contaminants. A260/280 primarily assesses protein contamination (phenol, aromatic compounds), while A260/230 assesses contamination from organic compounds (guanidine, EDTA, carbohydrates) and salts.

Q2: My RNA sample has an A260/280 ratio below 1.8. What does this mean, and how do I fix it? A2: A ratio <1.8 typically indicates protein or phenol contamination. To resolve:

- Perform an additional chloroform:isoamyl alcohol (24:1) extraction step.

- Follow with an ethanol precipitation and wash with 75% ethanol.

- Resuspend the pellet in RNase-free water or TE buffer (pH 8.0), not nuclease-free water which can be acidic and depress the ratio.

Q3: My A260/230 ratio is below 2.0. What contaminants are likely present, and what is the remediation protocol? A3: Low A260/230 suggests residual guanidinium thiocyanate (from TRIzol), EDTA, or carbohydrates. The remediation protocol is as follows:

- If guanidine/chaotropic salts are suspected: Perform a second ethanol precipitation with a sodium acetate (pH 5.2) wash. Increase the 75% ethanol wash volume and duration.

- If carbohydrate contamination is suspected (common in plant extracts): Use a more stringent homogenization protocol with polyvinylpyrrolidone (PVP) to bind polyphenols, followed by a lithium chloride (LiCl) precipitation step selective for RNA.

Q4: Both my A260/280 and A260/230 ratios are abnormal. What is the recommended comprehensive clean-up procedure? A4: Use a combined clean-up kit or protocol:

- Add 1 volume of 70% ethanol to the aqueous phase from an initial extraction.

- Pass the mixture through a silica-membrane column (e.g., Qiagen RNeasy).

- Wash with buffer RW1 (guanidine-based) and buffer RPE (ethanol-based).

- Elute in 30-50 µL of RNase-free water. This sequentially removes both protein and organic/salt contaminants.

Q5: My ratios are good (>2.0 for A260/280, >2.0 for A260/230), but my downstream application (RT-qPCR) fails. What could be the issue? A5: Good spectrophotometric ratios do not guarantee the absence of RNase or specific enzyme inhibitors (e.g., hematin from blood samples). Perform a spike-in control or use an assay like the Invitrogen Qubit RNA IQ Assay to detect degraded RNA. Consider using a DNase I treatment step if genomic DNA contamination is a concern.

Key Quantitative Data on Purity Ratios and Contaminants

Table 1: Interpretation of Nucleic Acid Purity Ratios

| Sample Type | Ideal A260/280 | Ideal A260/230 | Common Contaminants Lowering Ratio | Absorption Peak |

|---|---|---|---|---|

| Pure RNA | 2.0 - 2.2 | 2.0 - 2.4 | Phenol, Protein | 280 nm |

| Pure DNA | 1.8 - 1.9 | 2.0 - 2.4 | Phenol, Protein | 280 nm |

| Guanidine HCl | Variable | < 1.5 | - | 230 nm |

| Phenol | Variable | Variable | - | 270 nm |

| Carbohydrates | Variable | < 2.0 | - | 230 nm |

Table 2: Impact of Low Ratios on Downstream Applications

| Abnormal Ratio | Likely Contaminant | Impact on RT-qPCR (ΔCt) | Impact on Sequencing |

|---|---|---|---|

| A260/280 < 1.8 | Protein/Phenol | +2 to +5 Ct | Library prep failure, low yield |

| A260/230 < 1.8 | Guanidine/Salts | Inhibition, +1 to +3 Ct | Poor cluster generation, high error rates |

| Both Ratios Low | Complex Mixture | Complete inhibition | Total failure |

Detailed Experimental Protocols for Improving RNA Purity

Protocol 1: Chloroform Re-extraction and Ethanol Precipitation for Low A260/280

- Add an equal volume of chloroform:isoamyl alcohol (24:1) to your aqueous RNA sample.

- Vortex vigorously for 15 seconds.

- Centrifuge at 12,000 x g for 15 minutes at 4°C.

- Transfer the upper aqueous phase to a new tube.

- Add 1/10 volume of 3M sodium acetate (pH 5.2) and 2.5 volumes of 100% ethanol.

- Precipitate at -20°C for 1 hour.

- Centrifuge at 12,000 x g for 30 minutes at 4°C.

- Wash pellet twice with 75% ethanol (made with DEPC-treated water).

- Air-dry for 5-10 minutes and resuspend in 20-30 µL of TE buffer (10 mM Tris-HCl, 1 mM EDTA, pH 8.0).

Protocol 2: Lithium Chloride (LiCl) Precipitation for Polysaccharide and Polyphenol Removal (Plant/Fungal RNA)

- Following initial extraction, add LiCl to the aqueous RNA solution to a final concentration of 2.5 M.

- Incubate overnight at 4°C.

- Centrifuge at 12,000 x g for 30 minutes at 4°C to pellet RNA.

- Discard supernatant. Wash pellet with 70% ethanol (made with 2.5 M LiCl).

- Centrifuge again for 10 minutes.

- Wash pellet with 75% ethanol.

- Resuspend in RNase-free water or TE buffer.

Protocol 3: Silica-Membrane Column Clean-up (Combined Contaminant Removal)

- Adjust your RNA sample to 100 µL with RNase-free water.

- Add 350 µL of Buffer RLT (or equivalent lysis buffer) and 250 µL of 100% ethanol. Mix thoroughly.

- Apply the entire mixture (≈700 µL) to a silica-membrane column.

- Centrifuge at ≥8000 x g for 15-30 seconds. Discard flow-through.

- Add 500 µL of Buffer RPE (wash buffer). Centrifuge as before. Discard flow-through.

- Repeat the Buffer RPE wash. Centrifuge for 2 minutes to dry membrane.

- Elute RNA with 30-50 µL of RNase-free water by centrifuging at full speed for 1 minute.

Diagnostic Decision Tree for RNA Purity Issues

Title: Decision Tree for Diagnosing Low RNA Purity Ratios

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents for RNA Purification Troubleshooting

| Reagent / Material | Primary Function | Purity Issue Addressed |

|---|---|---|

| Chloroform:Isoamyl Alcohol (24:1) | Denatures proteins, separates organic phase from aqueous nucleic acid phase. | Low A260/280 (Protein/Phenol) |

| Sodium Acetate (3M, pH 5.2) | Salt for ethanol precipitation; neutral pH optimal for RNA recovery. | Low A260/230 (Salt co-precipitation) |

| Lithium Chloride (LiCl, 8M Stock) | Precipitates RNA selectively, leaving many carbohydrates and proteins in solution. | Low A260/230 (Polysaccharides) |

| RNase-free TE Buffer (pH 8.0) | Resuspension buffer; Tris maintains pH>7.6, EDTA chelates metals, protects RNA. | Depressed A260/280 from acidic water |

| Silica-membrane Spin Columns | Bind RNA under high-salt conditions; contaminants are washed away. | Combined low A260/280 & A260/230 |

| PVP (Polyvinylpyrrolidone) | Binds polyphenols during homogenization, preventing co-extraction. | Low A260/230 (Plant polyphenols) |

| DNase I (RNase-free) | Degrades genomic DNA contamination, which can skew ratios and downstream assays. | Not ratio-specific; general purity |

| β-Mercaptoethanol or DTT | Reducing agent added to lysis buffer to inhibit RNases and break disulfide bonds. | Not ratio-specific; protects integrity |

Troubleshooting Guides & FAQs

Q1: My RNA has a good A260/A280 ratio (>1.9) but a low A260/A230 ratio (<2.0). What does this indicate, and what are the primary culprits? A: A low A260/A230 ratio strongly indicates contamination with non-nucleic acid organic compounds or certain salts that absorb at 230 nm. The primary culprits, in order of likelihood, are: 1) Residual guanidine salts (e.g., from TRIzol or guanidinium isothiocyanate lysis buffers), 2) Phenol or phenol derivatives from the extraction process, and 3) Polysaccharides and polyphenols (common in plant or tissue samples). While A260/A280 reflects protein contamination, A260/A230 is a more sensitive metric for these specific contaminants, which can inhibit downstream enzymatic reactions like reverse transcription and PCR.